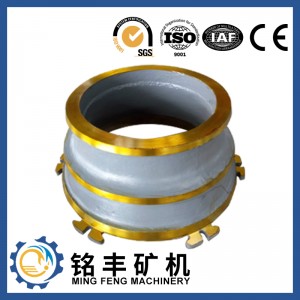

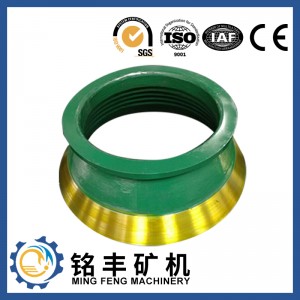

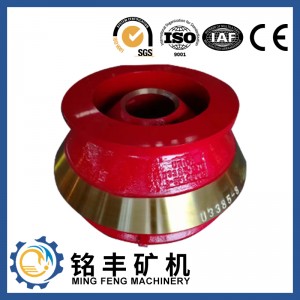

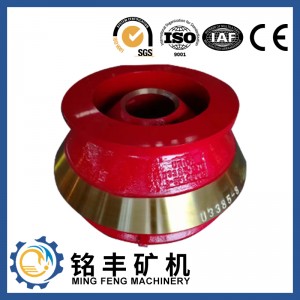

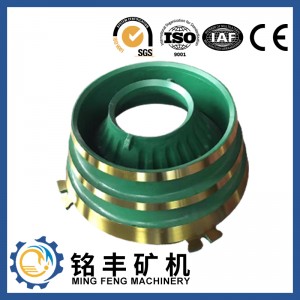

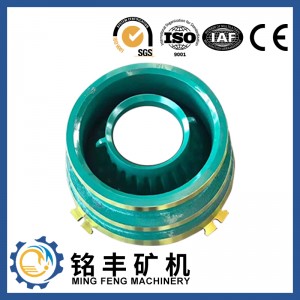

I-HP500 cone crusher cone liner kanye nesitsha se-SH F/M/C

INCAZELO YOMKHIQIZO:

I-Ming Feng MACHINERY ingumkhiqizi ochwepheshe we- HIGH MANGANESE STEEL CASTING PARTS,Imikhiqizo yenziwe ngezinto ezingavuthiwe zekhwalithi ephezulu, ngokusebenzisa isilinganiso sezakhi zesayensi nesamukelekayo (i-molybdenum, i-manganese, i-lanthanum yomhlaba eyivelakancane, njll.), encibilika esithandweni somlilo esiphakathi nendawo , ukwakha kanye, bese ngokusebenzisa uchungechunge lwezinqubo zokushisa ukushisa (ukushisa kokushisa kufinyelela ku-1045 degrees), ukuqina nokumelana nokugqoka kwemikhiqizo kungafinyelela izikhathi ezingu-1.2 kuya kwezingu-1.5 zemikhiqizo efanayo.Imikhiqizo yethu isetshenziswe kabanzi ezimayini, i-metallurgy, amandla ashisayo, usimende, izimayini zesihlabathi, i-golden panning nezinye izimboni

Imininingwane

1. I-HP500 cone crusher cone liner kanye nesitsha se-SH F/M/C

2. Durabale Performance

3. Isigqoko kanye ne-concave (i-bowl liner)

4.Insimbi Ephakeme YeManganese (Mn13Cr2, Mn18Cr2, Mn22Cr2 nezinto ezenziwe ngokwezifiso)

4. OEM iyatholakala

5.Isikhathi sokuhola:25-35days.

6.Over 30years isipiliyoni

Izinzuzo:

1.Ukulawulwa kwekhwalithi okuhle kakhulu kuthembisa ukusebenza okuphezulu.

I-2.Isikhathi sokuphila esifanayo nesiqinisekiso esifanayo nemikhiqizo ye-OEM yasekuqaleni.

3.Kuqinisekiswe isitifiketi sohlelo lwe-ISO.

I-4.Isikhathi esifushane sokulethwa, hlala ugcine inani elikhulu lempahla yekhasimende.

I-5.Intengo engcono kakhulu yesixazululo izosindisa inani elikhulu lezindleko zekhasimende.

I-Chemical Component ye-concave ne-bowl liner.

| Okubalulekile | C | Mn | Cr | Si | Mo | Ni | Cu |

| Mn13Cr2 | 1.0~1.4 | 12 ~ 15 | 1.7~2.2 | 0.3~1.0 | - | - | - |

| Mn18Cr2 | 1.0~1.4 | 17-19 | 1.8~2.2 | 0.3~1.0 | - | - | - |

| Cr12 | 2.0~3.3 | ≤2.0 | 11-14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr15 | 2.0~3.3 | ≤2.0 | 11-14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr20 | 2.0~3.3 | ≤2.0 | 14-18 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr26 | 2.0~3.3 | ≤2.0 | 23-30 | ≤1.2 | ≤3.0 | ≤2.5 | ≤2.0 |

OKUSHISAYO OKUDAYISWA

Ikhwalithi Okokuqala, Ukuphepha Kuqinisekisiwe