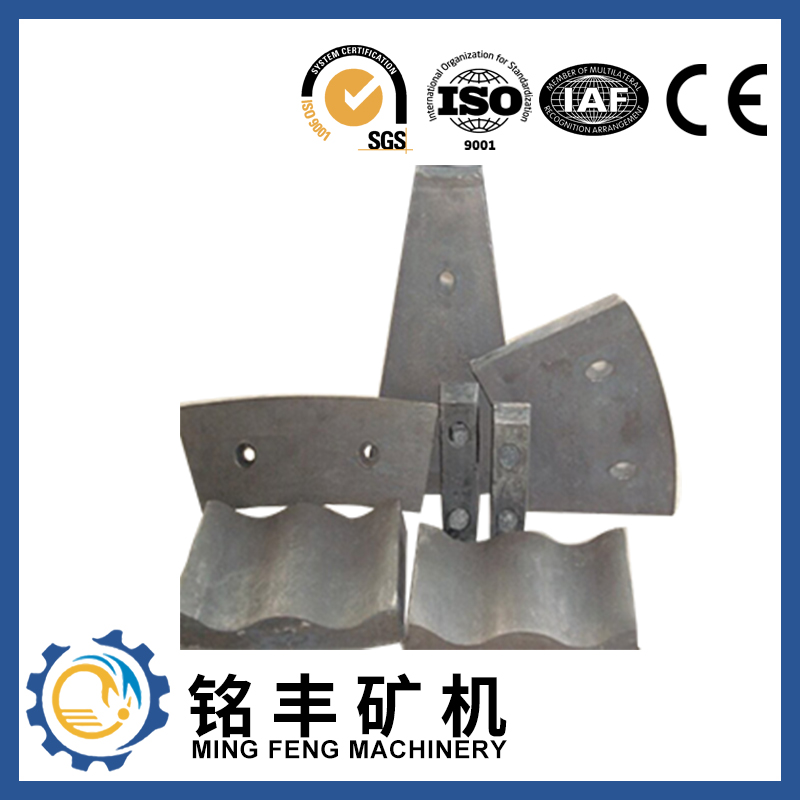

Crusher liner board/lining plate

Uhlolojikelele:

| Uhlobo | Crusher liner board, lining plate | ||

| Umsuka | China | Ikhodi ye-HS | 84749000 |

| Isimo | Okusha | Izimboni Ezisebenzayo | Amandla Nezimayini |

| Uhlobo Lomshini | I-Fine Crusher, i-Ball Mill, umshini wokugaya oqondile | Isitifiketi | ISO 9001:2008 |

| Izinto Ezibalulekile | I-alloy Steel, insimbi ye-Chromium alloy, Mn13, Mn13Cr2 | ||

| Uhlobo Lokucubungula | Iyasakaza | Ukwelashwa Okungaphezulu | Ukupholisha/Fafaza-Upende |

| Ukuhlola Ukusakaza | I-Spectrum Instrument efunda ngokuqondile, Ukuhlaziywa kwe-Metallographic, Ukuhlolwa kwe-Ultrasonic, Ukuhlolwa Kwezinhlayiya Ezizibuthe, Ukuhlolwa Kwezakhiwo Zemishini | ||

| Iphakheji Yezokuthutha | Ipakishwe ku-Pallet/Case | Isiqinisekiso | Okufanayo nokwangempela |

| Ikhwalithi | Izinga eliphezulu | Isipiliyoni | Ngaphezu kweminyaka engama-30 |

Uchungechunge Lomkhiqizo:

1.Uchungechunge lwensimbi ephezulu ye-manganese

Izinto ezingagugi ezisetshenziswa kakhulu kwezensimbi, izimayini kanye nemishini yokuchoboza, okuhlanganisa insimbi evamile ye-manganese ephezulu, insimbi eguquliwe ephakeme ye-manganese, insimbi ye-manganese ephakeme kakhulu, ingxube yezingxenye eziningi ecutshungulwe kakhulu insimbi ephezulu ye-manganese kanye nozibuthe wensimbi ephezulu ye-aluminium. amapuleti lining.

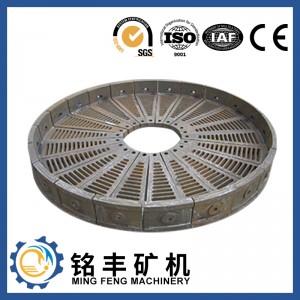

2. Uchungechunge lwensimbi ye-alloy ephakathi nephansi

Le mikhiqizo isetshenziswa kakhulu ezingcwecweni zamapulangwe ezitshalo zikagesi, izitshalo zamalahle, nezinye izigayo zamabhola ezimayini, eziphawuleka ngokuguquguquka okuhle, ezingaguquki, ezingaphukanga kanye nokuphila isikhathi eside kwensimbi yemanganese ephindwe kabili.

3.Uchungechunge lwensimbi ephezulu ye-chromium

Le mikhiqizo isetshenziswa kakhulu emikhakheni yokuphahlaza noma ye-matallurgy, yezimayini kanye nekasimende, elungele ukuphonsa umthelela omaphakathi. Ngokusebenza kahle kwezindleko nokumelana nokugqokwa komsindo, ihlukaniswe ngamaqembu amane ngokuya ngemibandela yesevisi: KmBCr15, KmTBCr20, KmTBCr26 kanye uhlobo oluhlanganisiwe.

4.Uchungechunge lwemikhiqizo evimbela ukugqokwa kwenhlanganisela

Indlela yokumelana nokugqokwa kwe-Hardfacing kanye ne-bimetal compound casting technique iyamukelwa ukuze kwenziwe imikhiqizo eqinile engagqoki, enezici zokuba lula ukucutshungulwa kanye nekhono eliqinile lokumelana nokugqokwa.

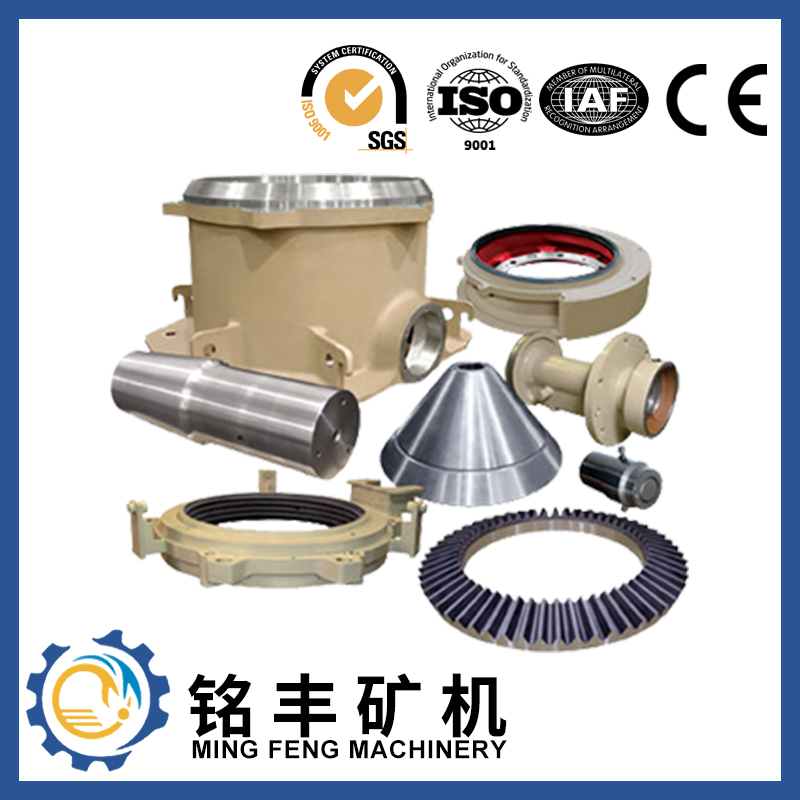

Izingxenye ze-Crusher:

Sinezingxenye ezisele zomshini ezifaka umshini wokufaka esikhundleni se-crusher ezihlanganisa ikhanda, izitsha, i-main shaft, i-socket liner, isokhethi, i-eccentric bushing, i-head bushings, igiya, i-countershaft, i-countershaft bushing, i-countershaft housing, i-liner yesihlalo esikhulu nokunye, singasekela umshini wakho wonke izingxenye ezisele zemishini.

Kungani ukhethe thina?

Iminyaka engu-1.30 yesipiliyoni sokukhiqiza, iminyaka engu-6 yesipiliyoni sohwebo lwangaphandle

2.Ukulawulwa kwekhwalithi okuqinile, ilabhorethri Yakho

3.ISO9001:2008, BUREAU VERITAS

OKUSHISAYO OKUDAYISWA

Ikhwalithi Okokuqala, Ukuphepha Kuqinisekisiwe