Isitsha sokugaya ibhola selabhu

Incazelo:

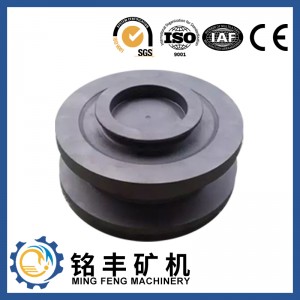

Isitsha sokugaya i-Tungsten carbide sinobulukhuni obukhulu, ukumelana nokugqoka, amandla amahle nokuqina, ukumelana nokushisa, ukumelana nokugqwala kanye nochungechunge lwezakhiwo ezinhle kakhulu, ikakhulukazi ubulukhuni bayo obuphezulu nokumelana nokugqoka, ngisho nangaphansi kwezinga lokushisa elingu-500 ℃ liyisisekelo lihlala lifana, ku-1000 ℃ isenobunzima obuphezulu.

Esetshenziswa kabanzi ezempi-yezimboni eziyinkimbinkimbi, zezindiza, imishini, metallurgy, ukumba uwoyela, amathuluzi ezimayini, ezokuxhumana ngogesi, ukwakhiwa kanye neminye imikhakha, kanye nokuthuthukiswa izimboni ezansi nomfula, carbide okwandisa isidingo emakethe.Futhi ikusasa lezikhali ezintsha neziphakeme zobuchwepheshe kanye nokukhiqizwa kwemishini, inqubekela phambili yesayensi nobuchwepheshe kanye nokuthuthukiswa okusheshayo kwamandla enuzi, kuzothuthukisa ukuzinza kokuqukethwe kobuchwepheshe obuphezulu kanye nekhwalithi ephezulu yesidingo semikhiqizo ye-alloy eqinile.

Izinzuzo:

1. izinga eliphezulu eliqhubekayo

2. ezinsukwini ezingu-30 isikhathi sokulethwa kokukhiqizwa kwenqwaba

3. isevisi enhle ngaphambi nangemva kokukhiqiza

4. ukulawula okuqinile ekutholeni impahla eluhlaza nangemva kokuhlolwa kokukhiqiza

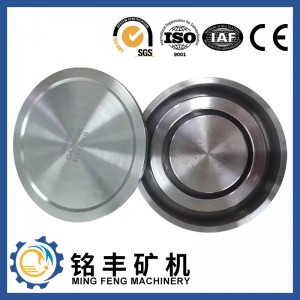

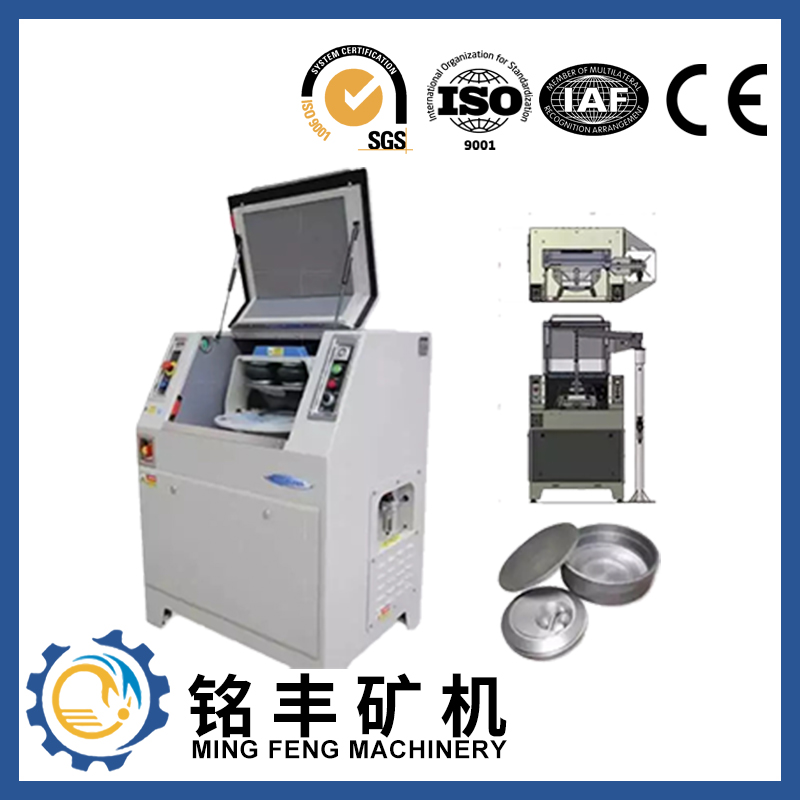

Isethi yesitsha sokugaya i-Laboratory Pulverizer Mill:

Isethi yesitsha sokugaya i-Laboratory Pulverizer mill yenziwe nge-Steel 65Mn noma i-Cr12, ingxenye ingenziwa ngensimbi ye-carbon steel, insimbi empunga, i-ductile iron nayo, isetshenziselwa isampula laselabhorethri.

Izingxenye zokuphonswa kwensimbi nezingxenye zokusansimbi zensimbi ezivela embonini yami zidayiselwe amazwe amaningana ahlukene, futhi zithole isikweletu esihle kumakhasimende ngekhwalithi ephezulu engaguquki kanye nesevisi ecabangelayo.

Sicela usithinte ngesidingo sakho esithile:

1.Ibanga kanye nosayizi othize noma umdwebo

2.Ubuningi kanye nekhwalithi.

3. Indawo yokusebenza,

4.Ezinye izidingo ezikhethekile.

OKUSHISAYO OKUDAYISWA

Ikhwalithi Okokuqala, Ukuphepha Kuqinisekisiwe